FLUKE II905 INDUSTRIAL ACOUSTIC IMAGER

FLUKE II915 INDUSTRIAL ACOUSTIC IMAGER

Efisiensi Energi Dimulai dari Deteksi Kebocoran yang Tepat

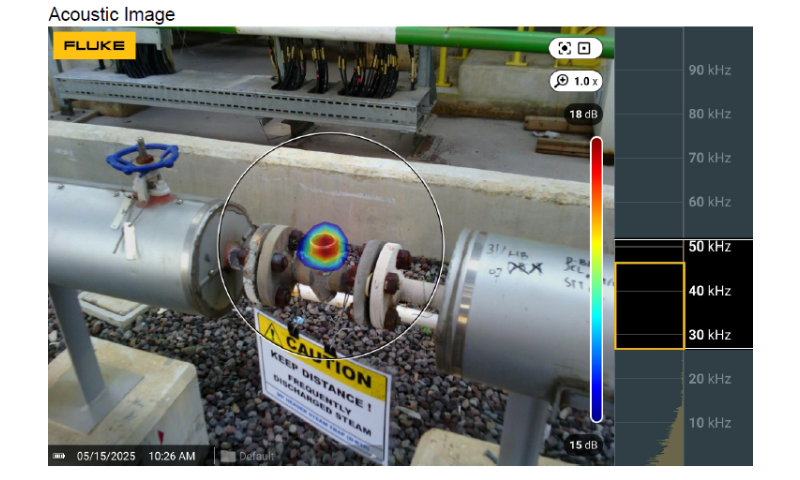

Dalam kunjungan teknis ke beberapa fasilitas industri, tim PT Bimura Putra Persada (Murada) melakukan demonstrasi Fluke ii915 Acoustic Imager, alat canggih yang mampu mendeteksi kebocoran udara bertekanan atau uap yang tidak terlihat mata, hanya dalam hitungan detik.

Hasilnya? Beberapa kebocoran berhasil terdeteksi, dengan potensi penghematan energi dan biaya yang signifikan jika segera ditangani.

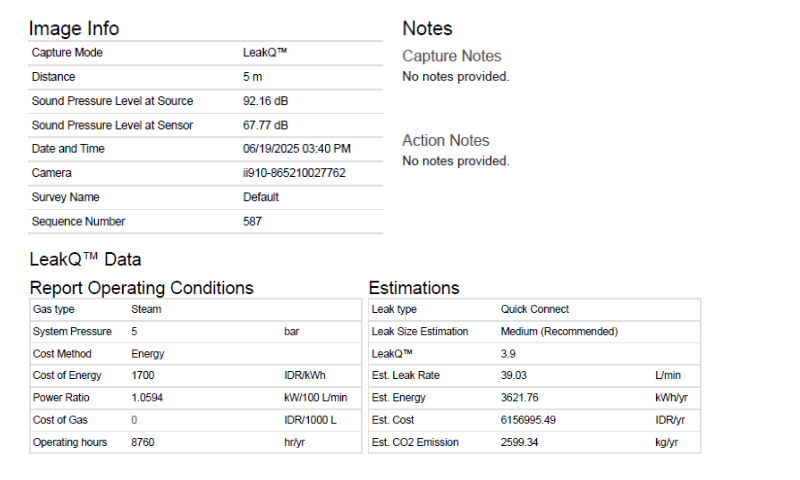

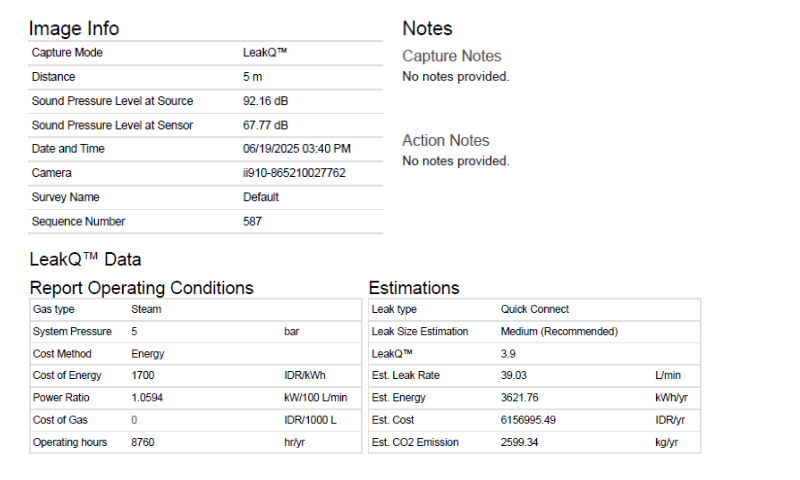

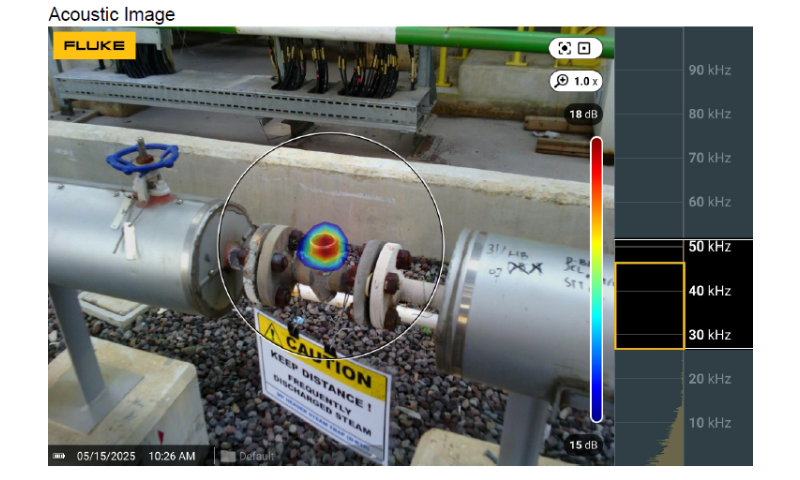

Temuan 1 — Pipa Uap Utility (Tekanan Sistem: 5 bar, Gas Type: Steam)

- Jenis Kebocoran: Quick Connect (Medium)

- Laju Kebocoran: 39.03 L/min

- Estimasi Energi Hilang: 3621.76 kWh/tahun

- Kerugian Biaya: ± IDR 6,156,995/tahun

- CO₂ Emission: 2599.34 kg/tahun

Kebocoran uap seperti ini tidak hanya memboroskan energi, tetapi juga berpotensi mengganggu keselamatan kerja di area bertekanan tinggi. Deteksi dini menjadi langkah krusial untuk pencegahan.

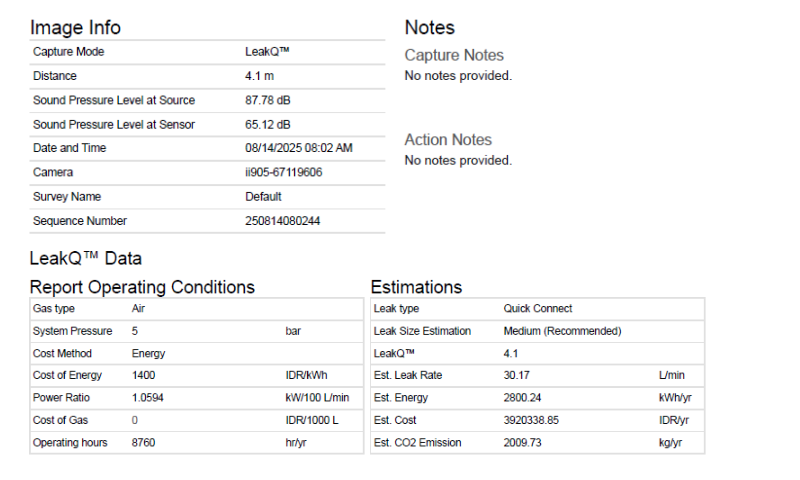

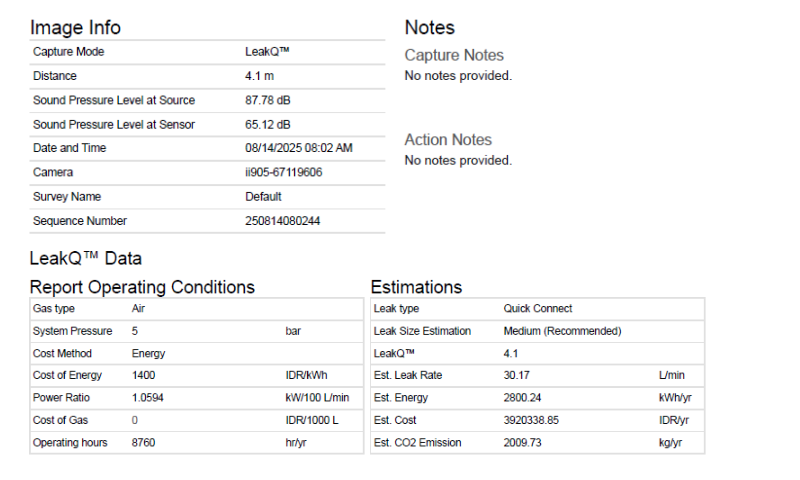

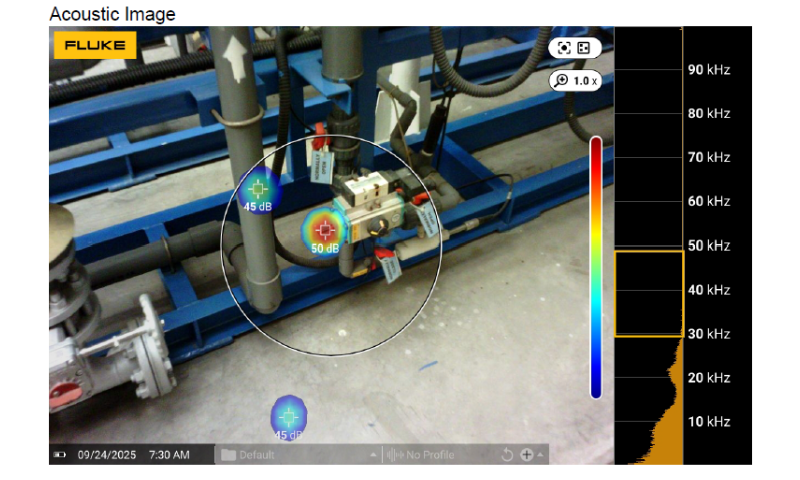

Temuan 2 — Jalur Produksi Utility (Tekanan Sistem: 5 bar)

- Jenis Kebocoran: Quick Connect (Medium)

- Laju Kebocoran: 30.17 L/min

- Estimasi Energi Hilang: 2800.24 kWh/tahun

- Kerugian Biaya: ± IDR 3,920,338/tahun

- CO₂ Emission: 2009.73 kg/tahun

Kebocoran signifikan ditemukan di titik sambungan cepat (quick connect). Kondisi seperti ini sering luput dari inspeksi rutin, namun bisa menyebabkan kerugian besar pada sistem udara terkompresi.

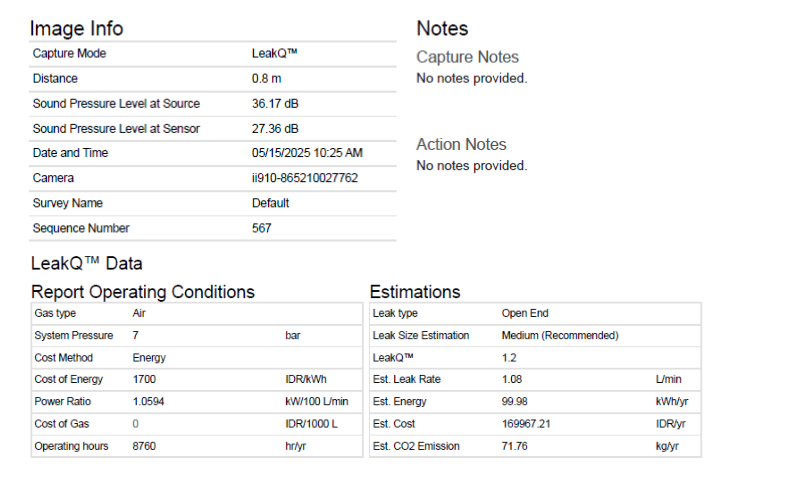

Temuan 3 — Pipa Udara Terbuka (Tekanan Sistem: 7 bar)

- Jenis Kebocoran: Open End (Medium)

- Laju Kebocoran: 1.08 L/min

- Estimasi Energi Hilang: 99.86 kWh/tahun

- Kerugian Biaya: ± IDR 169,967/tahun

- CO₂ Emission: 71.76 kg/tahun

Kebocoran ini ditemukan di area dengan paparan luar ruangan. Walaupun terlihat kecil, jika dibiarkan, kebocoran seperti ini bisa meningkatkan konsumsi listrik dan menurunkan efisiensi sistem kompresor.

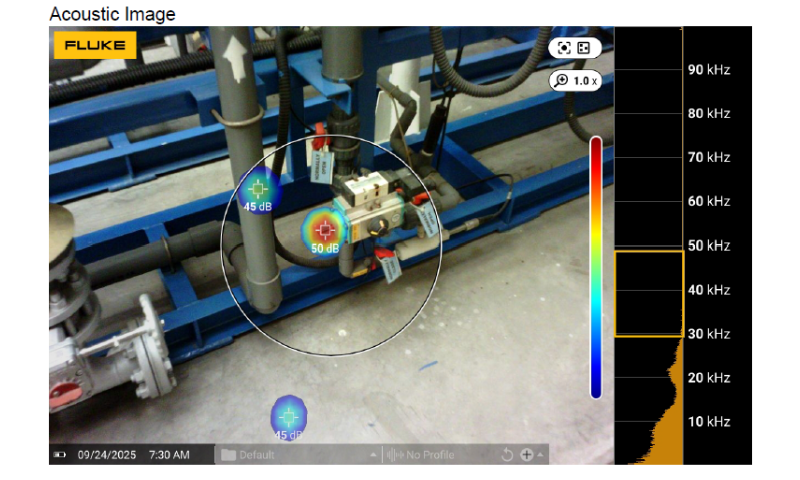

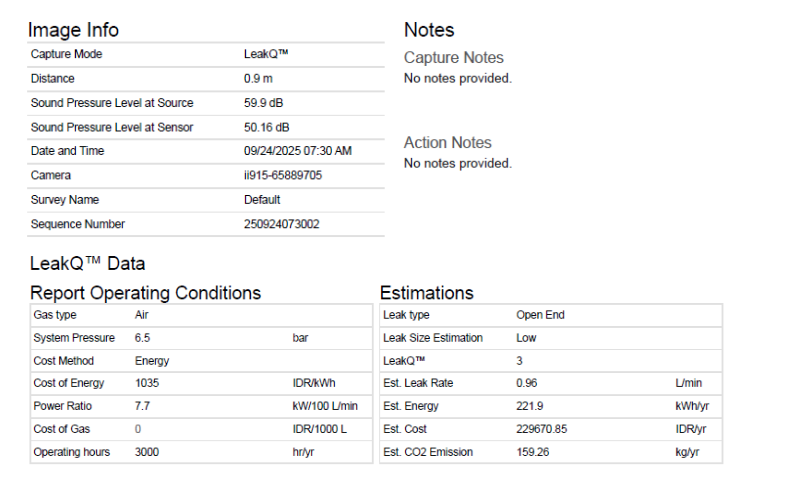

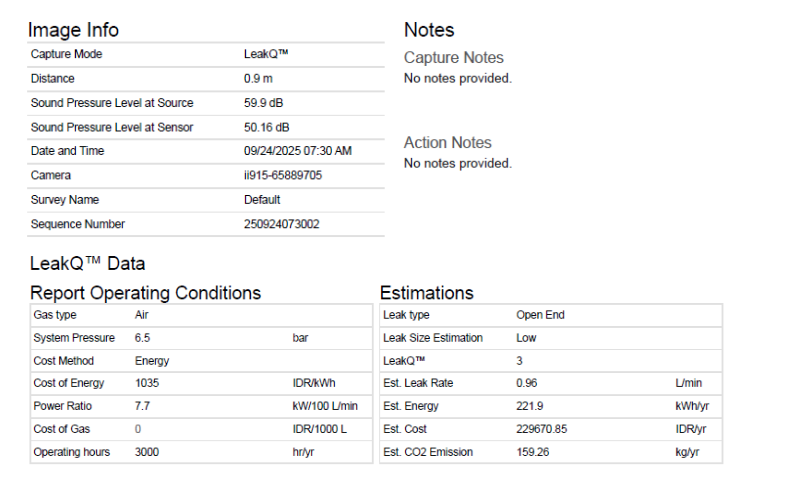

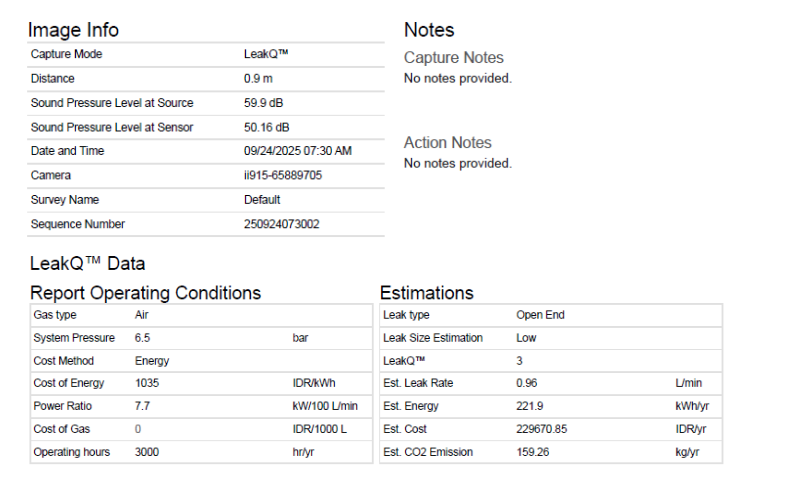

Temuan 4 — Pressure Regulator Constantly Leak (Tekanan Sistem: 6.5 bar)

- Jenis Kebocoran: Open End

- Laju Kebocoran: 0.96 L/min

- Estimasi Energi Hilang: 221.19 kWh/tahun

- Potensi Kerugian Biaya: ± IDR 296,870/tahun

- CO₂ Emission: 159.26 kg/tahun

Kebocoran akibat rusak nya pressure regulator mampu menyebabkan pemborosan energi yang tidak disadari. Dengan Fluke ii915, titik kebisingan ultrasonik langsung terlihat di layar, memudahkan tim maintenance menindaklanjuti secara cepat.

Kesimpulan

Dari hasil demo ini, jelas terlihat bahwa:

- Kebocoran kecil sekalipun berdampak besar terhadap biaya energi dan emisi CO₂.

- Deteksi dini menggunakan Fluke ii915 membantu tim maintenance menemukan kebocoran secara cepat, tanpa harus menghentikan operasi.

- Efisiensi energi dan keselamatan kerja meningkat signifikan hanya dengan inspeksi rutin berbasis akustik.

Ingin tahu seberapa efisien sistem udara bertekanan di fasilitasmu?

Hubungi tim Murada untuk jadwal demo Fluke Acoustic Imager dan temukan potensi penghematan energimu sekarang juga!

FLUKE II905 INDUSTRIAL ACOUSTIC IMAGER

FLUKE II915 INDUSTRIAL ACOUSTIC IMAGER

English:

Energy Efficiency Starts with Accurate Leak Detection

During a technical visit to several industrial facilities, the team from PT Bimura Putra Persada (Murada) conducted a demonstration of the Fluke ii915 Acoustic Imager, an advanced tool capable of detecting compressed air or steam leaks that are invisible to the naked eye — in just seconds.

The result?

Several leaks were successfully identified, revealing significant potential energy and cost savings if addressed promptly.

Finding 1 — Utility Steam Pipe (System Pressure: 5 bar, Gas Type: Steam)

- Leak Type: Quick Connect (Medium)

Leak Rate: 39.03 L/min

Estimated Energy Loss: 3621.76 kWh/year

Cost Loss: ± IDR 6,155,995/year

CO₂ Emission: 2599.34 kg/year

Steam leaks like this not only waste energy but also pose safety risks in high-pressure environments. Early detection is therefore critical for prevention.

Finding 2 — Utility Production Line (System Pressure: 5 bar)

Leak Type: Quick Connect (Medium)

Leak Rate: 30.17 L/min

Estimated Energy Loss: 2800.24 kWh/year

Cost Loss: ± IDR 3,920,338/year

CO₂ Emission: 2009.73 kg/year

A significant leak was discovered at a quick-connect joint. These areas often escape routine inspection but can lead to major losses in compressed air systems

Finding 3 — Open Air Pipe (System Pressure: 7 bar)

- Leak Type: Open End (Medium)

Leak Rate: 1.08 L/min

Estimated Energy Loss: 99.86 kWh/year

Cost Loss: ± IDR 169,967/year

CO₂ Emission: 71.76 kg/year

This leak was found in an outdoor-exposed area. Although seemingly minor, if left untreated, such leaks can increase electricity consumption and reduce compressor system efficiency.

Finding 4 — Pressure Regulator Constantly Leak (System Pressure: 6.5 bar)

Leak Type: Open End

Leak Rate: 0.96 L/min

Estimated Energy Loss: 221.19 kWh/year

Potential Cost Loss: ± IDR 296,870/year

CO₂ Emission: 159.26 kg/year

Leaks caused by damaged pressure regulators can lead to unnoticed energy waste. With the Fluke ii915, ultrasonic noise points are immediately visible on the screen, making it easy for maintenance teams to follow up quickly.

Conclusion

From this demonstration, it is clear that:

Even small leaks can have a large impact on energy costs and CO₂ emissions.

Early detection using the Fluke ii915 helps maintenance teams locate leaks quickly without halting operations.

Energy efficiency and workplace safety can be significantly improved through regular acoustic-based inspections.

Curious about how efficient your compressed air system is?

Contact the Murada team to schedule a Fluke Acoustic Imager demonstration and discover your facility’s energy-saving potential today!